Food

Research

To meet the demand for food due to an ever-increasing world population, commercial growers aim to increase the number of production cycles within a year. Speeding up the growth cycle for crops while still achieving the desired crop characteristics of height, finish or appearance and biomass are of utmost importance to growers in order to take produce to market faster and ensure long-term business profitability.

A plant’s height is significant to many growers, either as a visual indication of highest quality or the need to standardize commercial packages which requires a specific height at the end of production. Light quality and spectral control can be used as a vital tool for growers aiming to influence plant characteristics. This test was conducted with parsley by Heliospectra to understand how light quality can influence the height of a crop and by doing so also accelerate the production cycle. The goal was to find lighting strategy to accelerate production time by increase plant height to meet a certain height in fastest time possible but still maintain good crop quality.

Planting and Growth Conditions

The first part of the test started at the site of a commercial grower. The propagation of the parsley was done following their standard procedures. Parsley seeds were sown in plugs by the grower and placed in a germination area. After germination, the parsley plugs were brought into a vertical setup equipped with Heliospectra’s light bar. The spectrum composition of the light bar was a combination of blue (450nm), red (660nm) and white LEDs.

The parsley seedlings were grown under the light bar, after which the grower placed the plugs in pots and shipped the parsley pots along with some of their packaging bags to Heliospectra’s in-house plant lab. The end goal was to have the plants reach the height of the bags as fast as possible.

The full production cycle from seeding to harvest estimated by the grower (based on experience) was 33 days. After the re-potting of the plugs, 19 days were left to complete the production cycle.

Image 1: The plants upon arrival from the commercial grower

Lighting Strategies at Heliospectra’s In-House Plant Lab

The pots were placed in shelves built up in a 1.4m2 (15 ft2) open area with reflective curtains and an open front. The plants were grown under three different spectra respectively;

•Only PAR (a combination of blue (450nm), red (660nm) and white LEDs) and a light intensity of PAR at 200 μmol m-2s-1

•PAR + an additional Far-red with a light intensity of PAR at 180 μmol m-2s-1 (MidFR)

•PAR + an additional Far-red with a light intensity of PAR at 170 μmol m-2s-1 (HighFR)

Only PAR spectrum was within 400-700 nm region while the two others had far-red added to the spectrum. High FR had the highest amount of far-red of the total output while Mid FR had slightly less. All the spectra had the same electrical energy consumption.

Plant Height Measurements

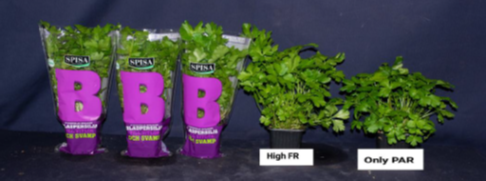

Measurements of the plants height were taken regularly to track when the plants had reach the desired height (to fill up the bag). Some of the parsley was harvested on the day when they reached the height of the commercial grower’s package, while the rest of the pots were left to grow under the different test spectra until the grower’s harvest date (day 19 of treatment). The first group that reached the targeted package height, was harvested at day 13 under the High FR spectra. The second harvest was at day 14 under the Mid FR. The last harvest to reach the targeted height at 19 days was the one grown under only PAR.At the final harvest at day 33 after seeding and after 19 days of light treatments, five pots of parsley grown under each spectrum was collected and measured. The fresh weight was recorded in grams and the height of each of the plants in centimeters. The pots of parsley harvested on days 13 and 14 were also measured using the same procedure when they reached the height of the growers packaging.

What’s more,on the final harvest day, after 19 days of treatment, the parsley grown with far-red showed an increase in both biomass and height with the increase in far-red.

Image 2: The average weight in grams and height in cm on day 19 of treatment and the pots harvested earlier on day 13 (High FR) and day 14 (Mid FR).

Although there was a lower biomass for the plants harvested earlier (on the days 13 and 14), the parsley reached the height of the grower’s package faster than the ones grown until day 19 with only PAR. The parsley harvested on days 13 and 14 still displayed good quality with consistent size, strong aroma and green even coloring of their leaves.

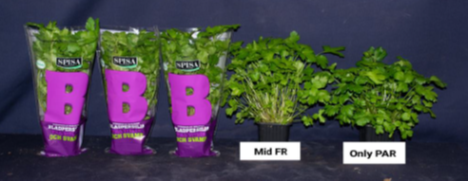

Image 3: Parsley at harvest,after 13 days of treatment, the four pots to theleft High FR and pot to the right Only PAR.

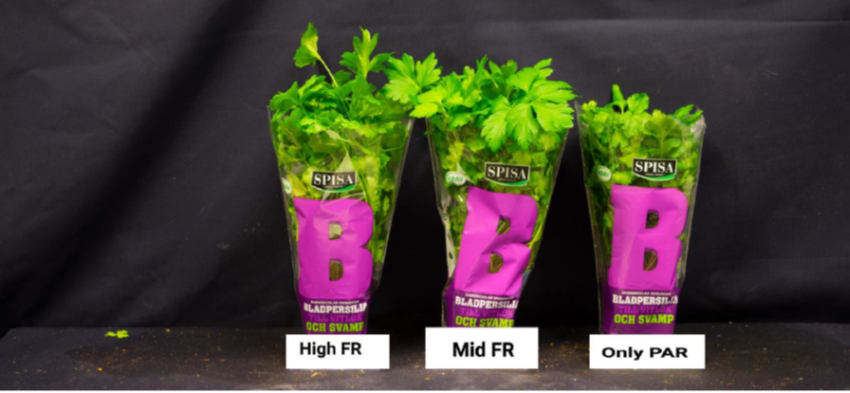

Image 4: Parsley at harvest after 14 days of treatment, the four pots to the left MidFR and pot to the right Only PAR.

The parsley grown under only PAR was more compact andhad a dark green color as compared to the parsley grown under a far-red spectrum. At day 33, after 19 days of light treatment, the parsley grown under the spectrum without far-red stayed compact and was the only batch that remained within the set goal height. The parsley grown under Mid FR and High FR treatments had all exceeded the height of the commercial growers’ packaging.

Image 5: Parsley at harvest, after 19 days of treatment, from left to right -High FR, Mid FR and Only PAR.

Using Light Strategies for Accelerated Harvest

Parsley grown under a far-red treatment had an accelerated harvest because they were able to reach the desired plant height before the plants grown without far-red and the growers’ estimated harvest date.

Although both the High FR and Mid FR grown plants had a lower biomass on the day they reached the desired package height, the produce filled the package, displayed desired plant characteristics and reached the standardized height faster. Some commercial growers may also contend that the longer stems or plant height at harvest time also makes harvesting, cutting, trimming and cleaning the plantsfor packaging faster, creating additional time savings. Growers may increase both plant height and biomass with far-red.

From the test results, a grower can accelerate crop harvest cycles and increase the total number of harvests across or within the year with the far-red spectrum. This offers the grower a cost-effective way to increase yields, crop quality and most importantly revenue. Additionally, the spectral composition with only PAR had a higher light intensity within PAR than the spectra with added far-red, butit was the last treatment to achievethe desired height for the parsley at day 19.

This demonstration is an example of the importance of understanding the specific spectra composition needed to achieve your crop performance goals. If your only focus is to get the most light output within PAR of a lighting system, the crop quality and growth efficacy is often overlooked.

Over the last 14 years, Heliospectra’s Technical Services team has continued to conduct commercial crop research in our in-house plant lab, collaborating with renowned research institutions and food producers to explore the effects of different spectrafor specific crops. We remain committed to helping commercial growers achieve business objectives while saving energy and improving both plant health and crop performance.

Ready to learn more about how your business can accelerate harvest cycles? Contact us

Related content

Get in touch with us!

From custom light planning, to tailored quotes, and everything in between,

our team of horticulture experts are always ready to assist.