Food

Research

Vertical Farming

Articles

Indoor and greenhouse growers who are contemplating the proper lighting equipment for their facilities inevitably arrive at the dilemma of HID versus LED. HID lights, which include high-pressure sodium (HPS) and metal halide (MH), are high-intensity discharge lights. The use of LED lamps for indoor and greenhouse commercial growth is surrounded by many myths. Five of the most common (but easily busted) LED myths to involve key performance indicators that help growers determine their final grow light choices, including:

- Cost/ROI

- LED lifespan

- Power consumption

- Heat/running temperature

- Crop yield

The US Department of Energy acknowledges that “LED is a highly energy-efficient lighting technology and has the potential to fundamentally change the future of lighting ….” However, not all LED lighting technologies are created equally. There are underpowered and inferior low-cost LED lamps on the market. Their poor performance negatively (and unfairly) affects the overall perception of genuinely reliable high-powered and high-performing units from market leaders. This is one reason why growers may be skeptical about LED technology. The following myths are also creating market confusion, so we are here to help set the record straight.

Busting 5 Common Myths About LED Grow Lights

#1. Cost and ROI

MYTH

“LEDs are not worth the higher initial cost when compared to competitive technologies, and the ROI has not proven itself.”

BUSTED

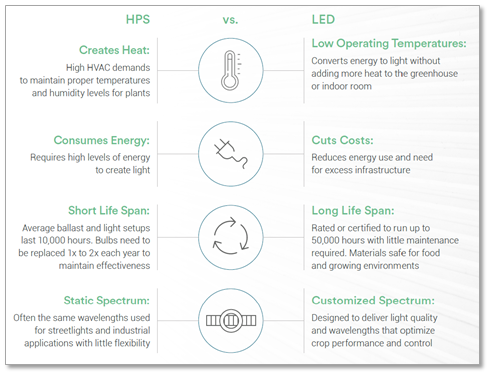

While the cost of LEDs alone could justify the investment, depending on one’s end goal, the cost is only one part of the equation. Commercial growers seek long-term solutions. The right LED lamp can deliver the ROI investor operators demand several times over. Though LEDs may require higher capital expenditure (assuming no subsidy, leasing, or an incentive program), LED lamps – with an expected lifespan of 50,000 hours – provide lower lifetime operating comparable expenses, if not significantly better, than HID systems.

LEDs provide both direct and indirect cost savings over traditional HID lighting technologies like HPS and MH. The direct savings come from the higher efficiency of LEDs, which use less wattage for a higher or similar level of light.

Direct Savings

HPS and MH lamps pull energy from both the light itself and the ballast, so a 1000W HPS light is actually pulling ~1100W, and a 1000W MH light is pulling ~1080W. Conversely, an LED light, such as Heliospectra’s MITRA, uses only the wattage of the light itself, so a 650W MITRA uses just 650W. Download our eBook for a complete breakdown of MITRA savings over HPS and MH lighting. The numbers may shock you. Why? LED electricity bills can run between 40-75% less than an equivalent HID or CFL (compact fluorescent light) system. This includes direct and indirect energy savings. It’s important to look at all savings from your entire system when calculating ROI.

Indirect Savings

Indirect energy savings using LEDs come primarily from lower HVAC (heating, ventilation, and air conditioning) needs. The plants also transpire less and so require less dehumidification. A breakdown of indirect savings can include:

- Lower maintenance costs: LEDs don’t need to be removed for servicing or cleaning, and most diodes are rated for 50,000+ hours of lifetime.

- Fewer consumables used: LEDs don’t require bulbs, ballast, or driver replacements.

- Less water used: Since plants transpire less, evaporation of the soil or medium is reduced.

- Lower cooling demand: LEDs radiate very little heat, so energy isn’t wasted on cooling the space and plants.

- Reduced infrastructure needs: LEDs can be placed close to plants, so infrastructure can be smaller and more economical.

LEDs eliminate years of new HID bulb and ballast purchases and enable lower upfront expenditure on HVAC and infrastructure.

Rebates & Incentives

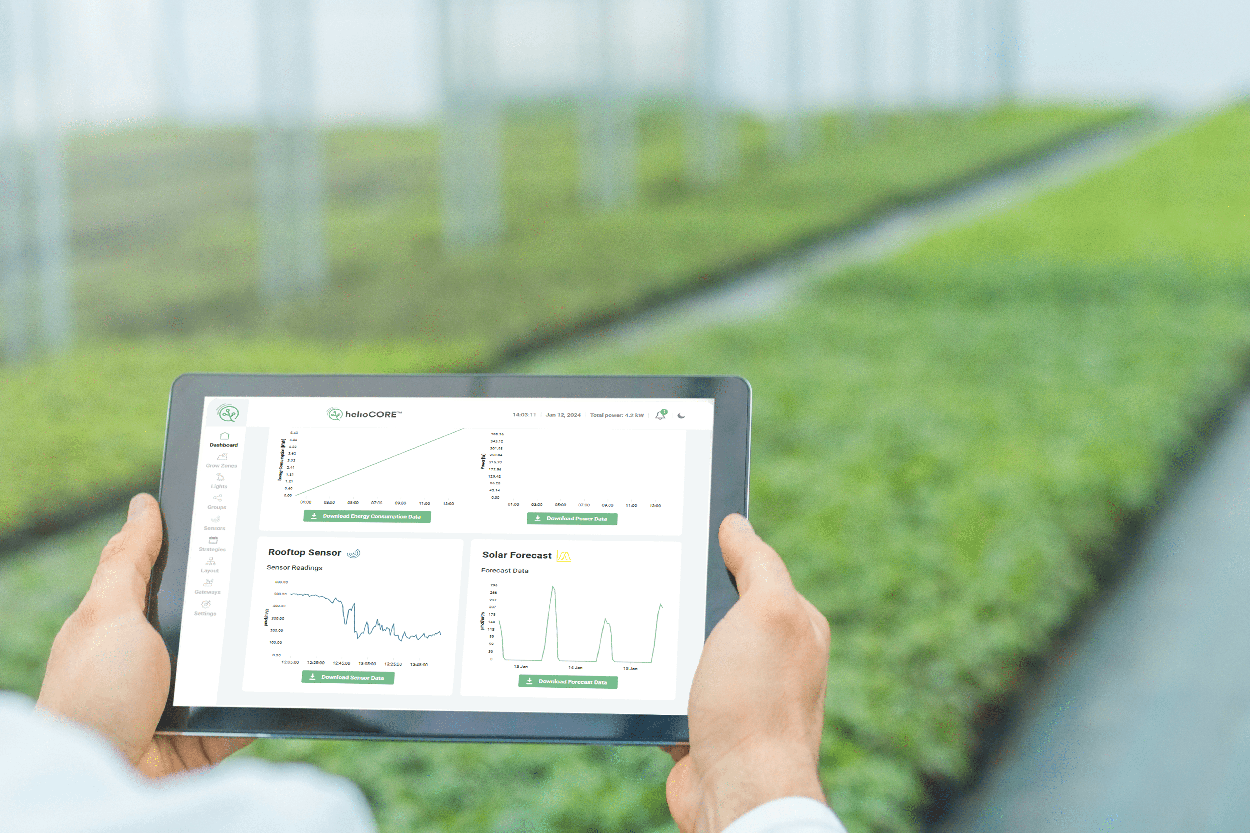

LEDs are receiving wide support from energy makers, who are offering rebates and incentives that can help you achieve ROI faster. Rebates per fixture can be in the $200-$350 range. Incentives can cover 25-50% of a new technology purchase and up to 100% of a retrofit. While investigating your options, remember some incentives cover not just the lights, but also the LED lighting controls like HelioCORE™, which can ensure you optimize your crops and energy usage all in one go. If you are wondering how rebates and incentives could benefit your business, comprehensive information on the offers available and how to apply can be found in our eBook Canada.

# 2. LED Lifespan

MYTH

“LED manufacturer claims about LED lifespan disguise real product failure mechanisms and mislead customers.”

BUSTED

LED-based products hold the potential to achieve lifetimes that meet and even exceed their traditional counterparts such as HPS fixtures. But manufacturer claims are often misconstrued by users who do not fully understand LED product failure mechanisms, nor see the difference between lifetime and reliability.

LED lumen (light output) depreciates at a much lower rate than other light sources. Where an HPS light depreciates within the first 6 to 9 months, an LED will reach the same level in 15 to 20 years. So, when you as a grower choose the best LED to grow lights, you will have the chance to grow crops for years without having to replace your lighting system.

Manufacturers rate most expected LED lifespans somewhere between 50,000 and 100,000 hours of use. In comparison, many other grow lights tend to last for around 20,000 hours before needing to be replaced. Besides decreasing long-term replacement costs there is also money to be saved in reduced maintenance costs and higher energy efficiency while improving light quality with lamps that last longer. As the U.S. Department of Energy (DOE) noted in their June 2020 Report on the Energy Savings Potential of SSL in Agricultural Applications, “LED lighting has surpassed all conventional lighting technologies in terms of energy efficiency, lifetime, versatility, and color quality.”

Operating temperature is also a major factor in LED lifespan, and we will talk further on about how LEDs operate at a much lower temperature than HPS, and how the little bit of heat output can be managed.

#3. Power Consumption

MYTH

“Energy savings from using LED lamps can’t be in the double digits, as manufacturers claim.”

BUSTED

Don’t just take our word for it, when Bridge Farm Group, one of the UK’s leading producers of plants, flowers and produce, installed MITRA lamps they achieved 40% energy savings compared to traditional HPS. At the same time, Heliospectra’s team helped them optimize their light output year-round and improve plant growth, aroma and taste. Read the full case study here.

LED grow lights are more energy-efficient than traditional LED technologies like HPS and metal halide, which have very high operating temperatures. A large portion of the energy consumed by these bulbs goes to heat radiation (infrared radiation). Infrared photons are not utilized by plants in photosynthesis but they warm up plants and the environment. When using HPS and other traditional lights in a warm climate or simply installing many fixtures in an area, plants can be easily overheated, causing you to need additional ventilation. As discussed in Myth #1 on costs and ROI, fans and air conditioning electricity consumption will add more energy demand to your grow facility.

LEDs are not just a replacement for HPS lights. HPS and other HID lamps cannot be placed close to the plants without burning them. Although LED lights, like every electric device, produce heat, their operating temperatures are much lower. They also do not emit heat radiation with their light. Therefore, they can be placed close to the plant canopy, saving space and reducing energy and infrastructure needs.

LED grow lights are constructed to emit light as a beam directed down. Traditional grow lights emit light in all directions, making them require hoods and reflectors to direct the light down to the plants. This equipment adds bulk and is not efficient in directing light to the plants, indirectly increasing energy consumption. High-quality LED grows lights are equipped with secondary optics. This helps to avoid “hot spots” (a concentration of light directly under the middle of a fixture) and distribute light evenly over the growth area. They also ensure that the photons are delivered directly to your crop.

A U.S. Department of Energy report examining the energy-saving potential of LED lighting in horticultural applications found that LED Grow lights offer a 24% to 30% reduction in electricity consumption compared to traditional horticultural lighting technologies. The study concluded that if all horticultural lights today were converted to LED technology it would represent a 40% energy savings or $240 million saved.

By 2027, the DOE reports that widespread use of LEDs could save approximately 348 TWh of electricity, which is equivalent to the annual electrical output of 44 large electric power plants producing 1000 megawatts each. To conserve energy, government, and utility organizations are offering discounts and incentives to encourage businesses to change their consumption behaviors, from decreasing energy demand to timing usage to off-peak hours. If your electricity bill is becoming an impediment to your operation, it is time to actively look into reducing your electricity usage. This eBook on Energy Use, Efficiency Strategies, and Opportunities for Incentives will take you step-by-step through an average energy bill and help identify ways to integrate efficiency into your system.

Even simple strategies like changing your lighting schedule can decrease your energy usage and improve your bottom line. Speak to your energy provider to find out which commercial incentives are available to you, and then talk to vendors about technologies that can help you benefit from those incentives. Intelligent LED technology and controls can certainly help you optimize your energy usage and time it to suit both your plants and your profitability.

#4. Heat or Running Temperature Management

MYTH

“Heat management could be the killer of horticultural LED lighting.”

This myth requires additional explanation: High-watt LEDs at fairly high densities are needed to obtain high light levels for photosynthesis. As the light output of LEDs seems to degrade mainly based on the temperature of the air around the LED dome, the problem with the current design of LED grows lights is the equipment needed to evacuate enough warm/hot air from the light and the air exhausts. At this stage, the equipment needed to cool down a high output LED is not efficient enough, and the few available are too expensive.

BUSTED

Thermal management of LEDs is a science in itself. The heat LEDs generate originates in the semiconductors due to slight inefficiencies resulting when electrical activity is not turned into light. But as LED grow lights have no filaments, they are generally more efficient in this area than HPS light sources and, therefore, produce less excess heat in indoor greenhouses.

Proper heat management is critical for LEDs, as increased heat affects the performance of the LED negatively, including a reduction in light efficiency, color shifts, and a reduction in LED lifespan. Since operating temperature is a major factor in the lifespan of an LED lamp, fixtures require a means for allowing warm air to escape. But as LED grow lights produce minimal heat, growers don’t need to spend a lot of time, energy, or expense dealing with excess heat when they can use small and reliable extractor systems for this purpose.

What is the best approach to keeping light arrays cool while keeping costs low? Water cooling is not 100% efficient at transferring heat, at least not yet. Locating the power supply outside of the growing area may give a grower half of the heat savings that could be realized with a water-cooled system, but what is gained in lower cooling energy is lost in line losses of long electrical cables.

Including fans (convection) to produce currents of cooling air is an effective way to manage heat issues, but fans introduce a moving part into the system. Moving parts typically break down long before LEDs fade. However, if you must purchase a unit with fans in it, make sure the LED grow lights have a long warranty and the fans are rated for a lifetime that exceeds that of the LEDs. Even better, MITRA avoids fans altogether with simple but highly effective passive cooling that ensures that the light and your growing room always remain at an ideal and consistent temperature.

No matter which lamps you choose, you should always ask the manufacturer for a light plan. Hanging grow lights in the right position and distance will allow your crops to utilize the photons to their full extent. Lights do not have to be static. LED grow lights enable a high level of control over the light output, especially when used in conjunction with smart systems like helioCORE™ to control your lighting, adjust your light intensity and alter your light duration to the changing conditions in your grow facility. Using intelligent lighting control, you can adjust the light intensity to the momentary requirements of your crops.

#5. Yield

MYTH

“LED technology is not capable of delivering the same yield as HPS and other HID technologies.”

BUSTED

Heliospectra lamps and other high-quality LED technologies have proven that yield is achievable. The primary reason yield has suffered (and continues to with low-quality lamps) is simple – lamps are generally incapable of pushing photons deep into the canopy in a uniform manner. Without optics, high-quality parts, superior engineering, and a highly engineered heat dissipation solution, an LED lamp will not deliver a comparable (much less good) yield.

However, proven LED technologies like MITRA have the power to increase yield, speed up production times, and improve crop quality for today’s growers. With its 3 customized spectra, MITRA has helped the Bridge Farm Group achieve higher yields as a result of the high-quality spectrum and the light output better penetrating the plant canopy. Read the case study or watch the 3-minute video to see how they achieved increased plant density, 10-day faster production, and more pots per growth cycle with MITRA.

Ontario’s Greenbelt Microgreens also “saw an immediate 13% increase in yield,” with Heliospectra lights, according to their Head Grower, Alice Farris. “Seasonal supplemental lighting maintains our crop quality, allows us to meet continual retail demand, and accurately forecast our yields,” comments Farris. Read the case study for more.

Our experience from working with our customers is that yield is achievable for both vegetable and flower crops. We help customers achieve faster time to market and better than average yields of higher-quality crops than HPS lighting.

SUMMARY

The following is a handy breakdown of the benefits of LED grows lights over HPS from our eBook on Producing High-Quality, Profitable Food Crops Faster.

WHY LED GROW LIGHTS ARE THE SMARTER LONG-TERM CHOICE

High-pressure sodium (HPS) lighting was revolutionary in its day. It succeeded in boosting yield but was hard to control. HPS fixtures are hot, inflexible, and power-intensive with a spectrum that is not necessarily optimized for plant cultivation. LED technology enables you to control growth in ways that HPS simply can’t deliver. So stop paying attention to misdirection and myths. With today’s MITRA lighting system and intelligent controls, your crops and business can target and achieve the desired outcomes. Check out MITRA now, or get in touch with us today!

ABOUT MITRA

MITRA’s features include a modular design, an innovative cooling solution, and IP67 dust and water resistance. Designed to work both indoors and in greenhouses, MITRA is available in a host of different modules and spectral options, making it the most versatile LED grow light on the market.

Key Features:

- Up to 2.8 μmol/J Fixture Efficacy

- 3 Customized Spectra

- Up to 40% decrease in energy consumption compared to HPS

ABOUT HELIOSPECTRA

“Heliospectra is not just selling a light, they continue to support and aid us as we learn – ensuring that our growers and the company as a whole are getting the most out of the investment.”

Andrew Fuller, Technical Director, Bridge Farm Group

Heliospectra AB was founded in 2006 in Sweden by plant scientists and biologists with one vision – to make crop production more intelligent and resource-efficient. Today, with customers across six continents, Heliospectra is the global leader in innovative horticulture lighting technology, custom light control systems, and specialized services for greenhouse and controlled plant growth environments. Designed by growers for growers, Heliospectra builds customized LED lighting strategies and controls that automate production schedules, forecast yields, and monitor crop health and performance with real-time data and response, delivering the light plants love and the consistent results growers need. For more information, please visit www.heliospectra.com.

The information herein has been carefully compiled and is believed to be accurate at the time of publication. It is meant to inspire you to dig deeper into the options and opportunities available. Heliospectra assumes no responsibility for possible errors, omissions, or consequences resulting from the use of this work.

Get in touch with us!

From custom light planning, to tailored quotes, and everything in between,

our team of horticulture experts are always ready to assist.